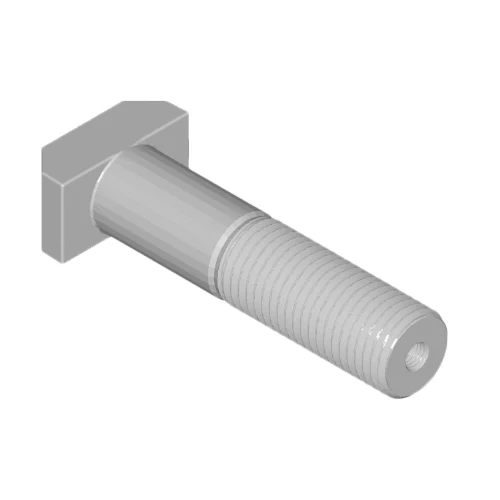

T Head Fastening Bolts

Send Inquiry

T head fastening bolts are available in a variety of materials. The choice depends on the application scenario and needs:

Carbon steel: Suitable for daily work, durable and affordable.

316 stainless steel: Chlorine and salt resistant, best suited for use in wet or salty environments (such as swimming pools or oceans).

Titanium alloy: Lightweight but strong, ideal for aircraft or aerospace equipment.

Alloy steel (such as 4140/4142): Used in high-temperature hydraulic situations that need to withstand extreme temperatures and pressures.

The bolt will have a code printed on it (such as A2-70) to indicate the specific material. Always check load charts to make sure the bolts can handle the stress in your project,this stops them from breaking too soon.

Maintenance

To make T head fastening bolts last longer:

Check them often for rust, worn threads, or bent heads.

Clean the T-slots with air to remove dirt and dust,this keeps the bolts sliding smoothly.

Lubricate threads with sticky stuff (like anti-seize) if they’ll be in high-heat areas.

Avoid chlorine cleaners on stainless steel bolts to prevent tiny holes.

Use a torque wrench to make sure they’re tight enough,don’t overtighten!

Replace bolts that look stretched or have messed-up threads right away.

Store them in dry places with silicone wraps to keep moisture out and stop rust."

FAQ

Q: What certifications do your T head fastening bolts comply with for international exports?

A: Our T head fastening bolts follow ISO 7380 (metric) and ASME B18.2.1 (inch) standards, so they’re sized and built to work properly. Stainless steel ones meet ASTM A193/A320 for high-pressure jobs, and we also have RoHS/REACH certificates for EU environmental rules. For aerospace customers, we offer NASM/MS-approved bolts.

We’ll give you material test reports (MTRs) and salt spray test papers (like 500+ hours for zinc coatings) if you ask. Our bolts comply with global quality and safety regulations.