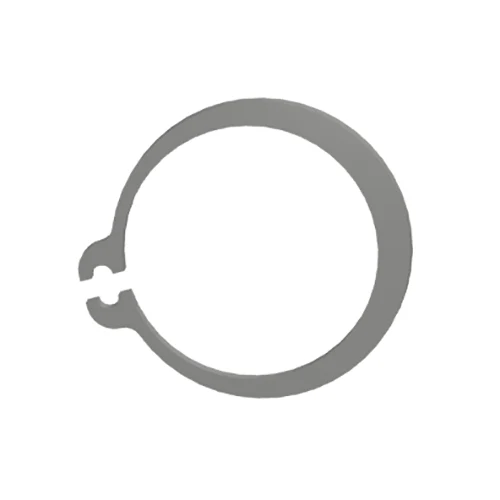

Circlips Retaining Rings for Shafts

Send Inquiry

Circlips retaining rings for shafts are fasteners made to hold parts on rotating shafts, stopping them from moving along the shaft in machines. These rings are round with open ends, so you can easily put them on or take them off using special pliers. They work well in high-stress situations, helping spread the load and keep things stable when they’re rotating.

You’ll see them a lot in cars, aerospace, and industrial gear. They’re known for being simple, tough, and cheap. They come in internal and external types, so they fit different shaft sizes and groove measurements. That makes them really useful for any machine setup that needs parts held securely along the shaft.

Product details:

The big thing about circlips retaining rings for shafts is they swap out parts that are a pain to thread or weld. That cuts down on time and costs when putting stuff together. They’re tiny but tough—they don’t hog space but still handle heavy loads. Made from materials like carbon steel or stainless steel, they hold up against wear, rust, and even crazy hot or cold temps. You can add coatings like zinc or phosphate if your setup needs something extra.

Product parameters

FAQ

Q:What materials are mostly used to make the circlips retaining rings for shafts and what are its benefits?

A:Most of them are made of carbon steel, stainless steel or heat-treated alloy materials. Carbon steel is a common material with relatively low cost and a significant price advantage. It also has good hardness and can withstand considerable external forces. Stainless steel is corrosion-resistant and has a good anti-rust effect, making it suitable for use in harsh environments, such as some damp or chemically corrosive environments. It can maintain good stability. Heat-treated alloys have higher strength and toughness, are less likely to deform, and ensure the safe and stable operation of equipment.

The material you choose decides how much weight the rings can take, how hot/cold they can get, and how long they’ll hold up. Like, stainless steel circlips are used in food machines since they don’t rust. Just make sure the rings meet standards like ISO 8752 to fit your shaft setup.